The Cook field is a small Upper Jurassic Fulmar field on the Western Platform of the Central Graben, UK Quadrant 21. It was discovered in 1983 by well 21/20a-2, with first oil produced in 2000. Ithaca Energy operates the field (61.3 %) with partners Ping (19.3%) and Hibiscus (19.3%). So far, the field over-performed, which triggered the company to further investigate arresting the natural decline.

The Fulmar reservoir in the Quad 21 area is mainly found in so-called inter-pods. These inter-pods are area between pods of Triassic mudstones of the Smith Bank Formation, which are grounded onto Permian carbonates or older rocks (see seismic line below). The Permian Zechstein salts that were initially deposited across the whole area now form the inter-pod areas where it moved into when the Triassic pods subsided into the Zechstein salt. Due to subaerial salt dissolution, the inter-pods constituted areas of low relief in Late Jurassic times, while the Triassic mudstones formed the more elevated areas. For that reason, when relative sea-level rose during the Late Jurassic, the shallow marine Fulmar sands were preferentially deposited in these valleys underlain by Zechstein salts.

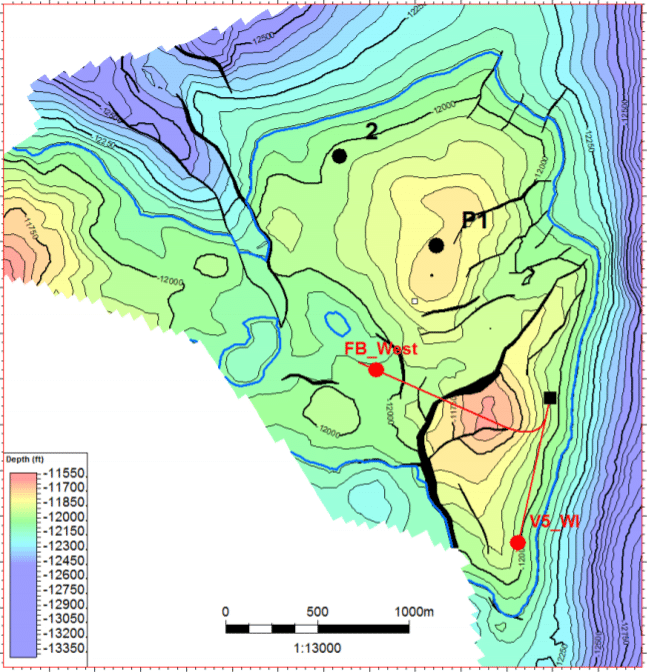

The single producing well in the field (21/20a-P1) has to date delivered >50 MMbls of oil, with no water production yet. However, with pressure declining to 2000 psi (from a virgin pressure of 9700 psi), the need for pressure support through water injection became more imminent. The question then arose as to where to drill this injector well.

With the field consisting of three compartments, of which only one was drilled, a decision had to be made on the best candidate for drilling the second well. Drilling the well into the already known compartment was not an option, because the distance between the producer and injector would have been too small.

Following careful planning, it was decided to penetrate the southern compartment (Well “V5-W1” on map above), with a fall-back option to drill the western compartment as a back-up. The main uncertainty was the fault that separated the southern from the main compartment. If it would have been a sealing fault, reservoir pressure could be around 9700 psi, but if the fault did not provide a seal, pressure may be as low as 2000 psi.

Upon drilling the Fulmar section, pressure points in the 21/20a-P2 well proved a light oil gradient with pressures between 2028 to 2078 psi, suggesting connectivity to the main compartment. However, even though the Oil-Water Contact was not drilled, it could now be estimated that the contact to be significantly deeper than in the Main compartment, which explained why the field has been overperforming.

This also led to the conclusion that the fault must have been sealing pre-production, but lost its sealing capacity during field life when the difference in pressure between both compartments became too large. According to the authors this is not uncommon and has been observed in more North Sea fields.

HENK KOMBRINK

The information for this article was sourced from a presentation delivered by Arvid de Groot at the Devex Digital Conference last month. The presentation is available online.